Electromagnets

Read more

-

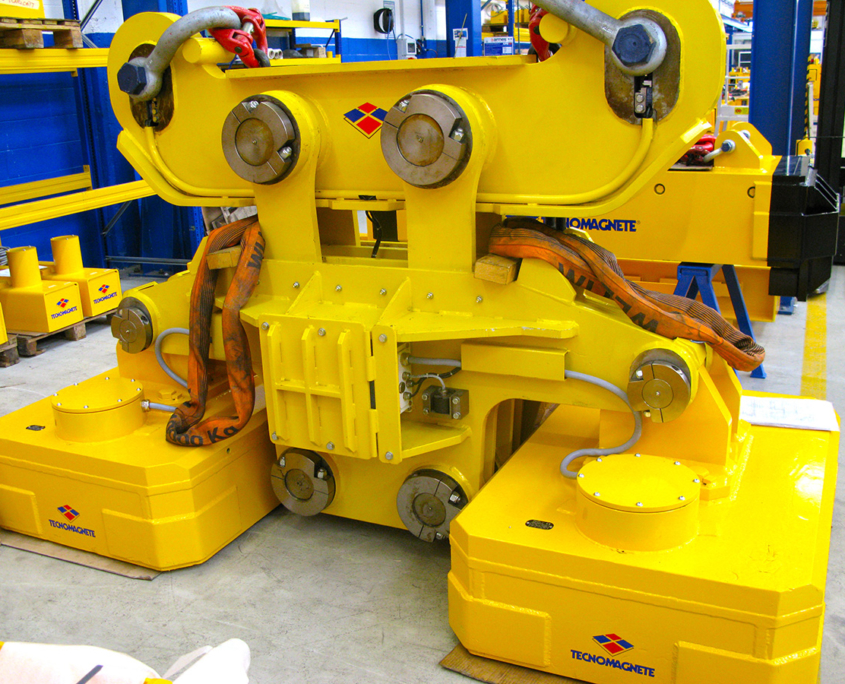

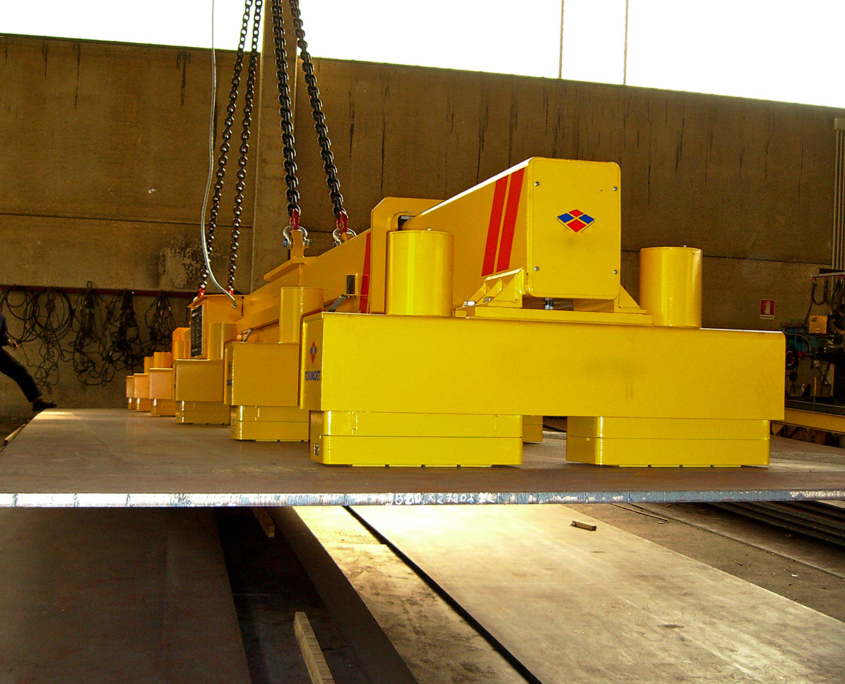

Movintech sells special deep field electromagnets for handling all types of bundles and packs of ferromagnetic material from 6 to 24 meters in length.

During the design phase, the weight of the magnets and the crossbeam is taken into great consideration in order to maximize the capacity of the lifting equipment. They are mainly used in the following applications:

• Electromagnetic crossbeams for Evacuation production of rebar for reinforced concrete, laminates, drawn bars, profiles and pipes (including hot materials).

• Magnetic crossbeam for Loading and unloading trucks, railway wagons or ships

• Magnetic crossbeams for Warehouses

Electromagnets in the evacuation of these long materials becomes more rational with the use of fewer people and a high degree of safety for the staff members themselves who are no longer required to approach the load or climb on it.

Handling with magnets makes it useless to position spacers between the bundles or single beams stored in the stalls; it is also possible to reduce or eliminate the free spaces between the stalls by increasing the available space in the warehouse.

The electromagnets are suspended from the crossbeam by means of chains that allow to adapt to the countless irregularities of the bundles.

Depending on the need, the electromagnets are designed with more active polarities thus obtaining high safety standards.

The main characteristics of our electromagnets are as follows:

• Magnetic circuit made of high permeability laminated steel with deep welds,

• External steel casing

• Aluminium or electrolytic copper winding

• Class C insulation (220°C)

• Thermal insulation (for heat resistant version only);

• Suspension with 4 leg chain made of Grade 80 steel.

The Electromagnets normally under fixed or multiple-arrangement crossbeams or extendable crossbeams allow, by adjusting the distance of the external magnets to adapt to the lengths of the bundles.

Considering the fact that handling with a single hook is especially difficult and requires the presence of an additional operator on the ground, it is advisable to handle the bundles with a 2-descent crane that allows the magnets to remain parallel to the load and prevents any oscillation.

The electromagnets are powered:

• from the mains by means of our electronic equipment with four quadrant digital converter with possibility of fluxomagnetic regulation, counter-excitation that allows a quicker release of the load, control of the winding temperature by means of current thresholds (useful especially for electromagnets in anti-heat version), automatic battery intervention system, buffer batteries (Pb or Ni-Cd), automatic recharging system and constant monitoring of the state of charge of the batteries.

Movintech always carries out handling operations using electromagnets – for any load, from scrap to laminates.

The lifting system with magnets is perfect for safety

ELECTROMAGNETS DESCRIPTION

The electromagnet is an electrotechnical element consisting of a core made of ferromagnetic material (usually soft iron) on which a solenoid – i.e. a coil of many coils of electrical wire – is wound.

The purpose of the electromagnet is to generate a magnetic field from an electric current and, for this reason, differs from the inductor, where the phenomenon of inductance is used to accumulate energy.

Characteristics

The intensity of the magnetic field generated can be calculated with the rules of magnetic induction, and essentially:

- it is proportional to the number of coils that constitute the winding. The increase in the number of coils and therefore in the length of the wire reduces the circulating current (with the same voltage) as a consequence of Ohm’s law, in order to solve the problem it is necessary to increase the section of the wire in order to decrease its electrical resistance.

- it is proportional to the current circulating in the winding, the crossing of current, generates heat produced by Joule effect, it must therefore be remedied by disposal.

As regards the force developed by the magnetic field, its intensity decreases with the square of the distance between the parts, so the electromagnet is effective only at short distance.

If the coil is supplied with a variable current, the magnetic field is in turn variable and so is the force produced.

In the calculation of electromagnets with variable currents, the effect of inductance at different frequencies must also be taken into account.

In addition, to avoid the formation of eddy currents in the core, this is done with thin plates rather than a compact block, exactly as in the transformer.

High field strength

For the listed reasons, non-superconductive electromagnets are suitable where impulsive, non-permanent magnetic fields are required.

Type of electromagnets.

Electromagnets for bars

Electromagnets for sheet metal

Electromagnets for wire rod

Electromagnets for scrap

Electromagnets for iron rebar