Chains

Read more

Movintech lifting and anchoring slings guarantee safety when lifting and handling loads. More than 550 different innovative eyebolt lifting / anchoring solutions (weldable or screwable), together used with our grade 80 and grade 100 lifting chains meet the highest requirements in all areas of application in the evolution of anchoring and lifting.

For the use of chain slings it is necessary to comply with the provisions of the Accident Prevention Association Regulations of category BGR 500 / DGUV 100-500, chapter 2.8 “Management of load-bearing equipment used as lifting systems” and the corresponding country-specific regulations (other countries). Wherever possible, it is absolutely necessary to keep away from the danger zone. Suspended loads must never be left unattended.

Make sure before use that:

1) the chain sling corresponds to what was ordered

2) the test certificate (in accordance with DIN 10204 with the specifications of UNI EN 818-4) and the declaration of conformity are available.

3) The details indicated on the chain sling identification plate correspond to the data contained in the test certificate and declaration of conformity.4) The details are recorded in the chain specifications file.

This documentation must include a description of the chain assembly as well as its traceability (test certificate, declaration of conformity ref.no).

Chain slings must be used with a straight boom, without any twisting, knots or creases.

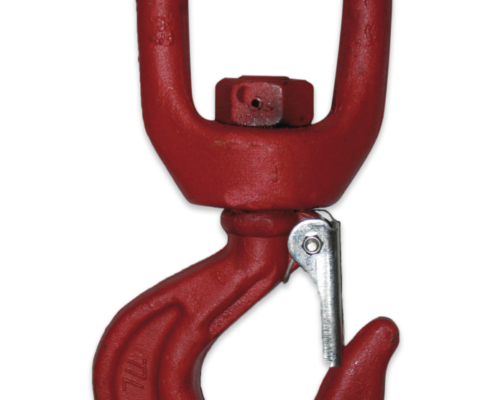

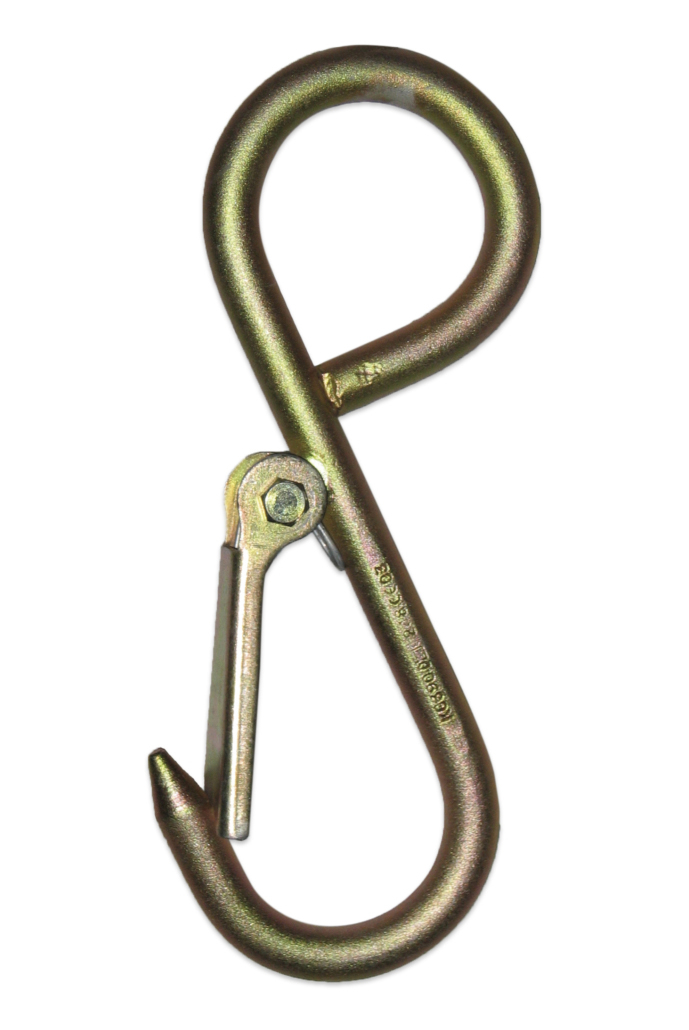

The lifting hooks must not be stressed at the tip.

They must be secured to prevent against accidental release.

Before using hooks without a safety device, a complete risk assessment must be carried out and the use must always be strictly controlled.

When using chain shorteners according to DIN 5692:2011-4, all technical requirements of the standard must be met.

The bells must rest on the base of the hook and move freely.

Avoid shocks and tears to the chain.

Sharp edges bend and damage links and chain components.

In this case, if possible, protect the chain from sharp edges, alternatively use a larger chain diameter or reduce the WLL by 20 %.

When components are modified by the user, the health and safety requirements must be redefined and the risk assessment must be reconsidered by taking the appropriate corrective action.

FOR SAFETY

Modern production facilities and strict controls guarantee the highest degree of safety.

FOR ASSEMBLY

Different tie rod assembly systems are available to meet any request.

Technical data

– Elongation at break: min 20%

– Workload stress: 250 N/mm2

– Stress at test load:625 N/mm2 during production

– Breakage stress:1000 N/mm2

– Minimum bending test 0.8 x d

– Maximum permissible temperature 200°C

APPROVAL

The chains are manufactured in accordance with ASTMA973/A973M-01, EN 818-2 but with capacities exceeding those of the Machinery Directive 2006/42/CE.

The components are manufactured in accordance with EN 1677.

The Quality System guarantees the consistent high quality of the chains and complies with ISO 9001.

MARKINGS AND TESTS

The chains are marked with the manufacturer’s identification symbol and the quality grade.

In addition, each link is marked.

All chains, without exception, are tested at least 2 times their limit load.

All tie rods are delivered complete with metal identification plate and CE declaration of conformity.