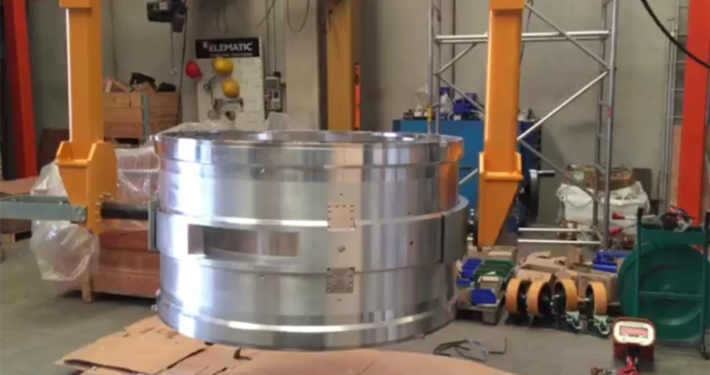

GRIPPERS FOR COILS

Automatic grippers for lifting of strapped coils. Various configurations and capacities up to 40 tons

The 360° rotation, if provided, is controlled by an inverter-driven motor coupled to an irreversible orthogonal gear reducer, so as to ensure that the rotation lock is maintained. The rotation speed will be 1-2 revolutions per minute, the application of the inverter allows to optimize the acceleration/deceleration ramps and the rotation speed according to the stability of the crane hook block and the customer’s production needs.

The gripping of the pack is performed with two parallel crossbeams each having 4 feet which can be either fixed or rotating, they slide on wear-resistant material inside the central body of the gripper in slots obtained by machining the machine tool and controlled by a motor driven by inverter coupled to an irreversible orthogonal gear reducer with closing speed of 8 m/min.

The application of the inverter allows to optimize the closure of the brackets according to the customer’s needs.

A clutch is applied on the slow axis of the crossbeam drive reducer to protect the entire kinematic system against accidental impacts.

All operations are carried out after thermal stretching of the steel framework with a stay in the oven of at least 24 hours.

GRIPPER DESCRIPTION:

The gripper is composed of a central body made of weldable steel, on the top, on a surface machined to the machine tool is fixed the rotation washer located on the lower side

to the attachment of the crane’s stabilized crossbeam, while internally the C-shaped coil gripping hooks slide.

On this structure the control motor is fixed, as well as the 2+2 pulleys supplied by the crane manufacturer, the junction box of the system on board the gripper and the connector for the cable reel connection.

The structure is manufactured according to structural group A7 and class M7 mechanisms of the FEM standards.

The anchoring of the gripper to the crane is done by means of a double rope lowering as shown in the diagram below.

The grip of the coil is performed with two motorized C hooks, which slide on wear-resistant material inside the central body of the gripper in slots obtained by machining the machine tool and controlled by a 1.85kW power motor driven by an inverter coupled to an orthogonal irreversible gear reducer with closing speed of 8 m/min.

The application of the inverter allows to optimize the closing of the two C hooks according to the customer’s needs.

A clutch is applied on the slow axis of the C hooks drive reducer to protect the entire kinematic system against accidental impacts.

On the support feet of the coil, a load presence sensor is applied that excludes the gripper opening commands during aerial movement and blocks the travel and sliding movements when only one of the two is operated.

The feet of the C-shaped hooks, in the coil support area, are interchangeable and made of hardened steel.

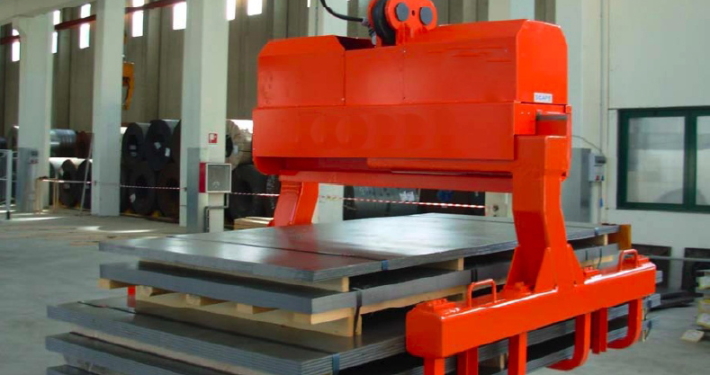

Variant of the coils grippers are the grippers for sheet metal packs and for slabs.