Lifting suction cups

Lifting suction cups

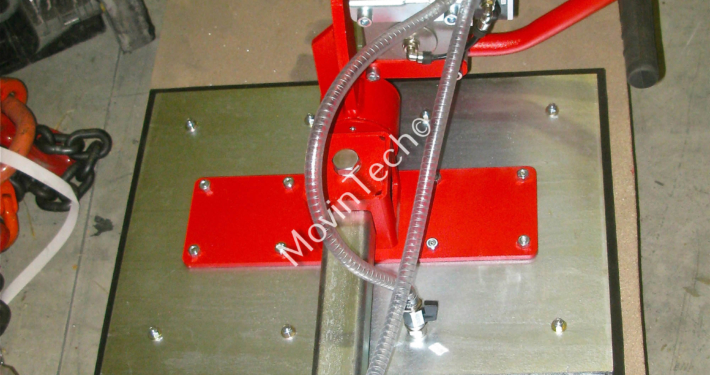

The system normally consists of the vacuum pump + connection pipe + suction cup.

The vacuum pump must be positioned close to the place of use.

For special applications we supply pumps with single-phase electric motors, direct current (for installation on self-propelled vehicles powered by the batteries of the vehicle itself), with internal combustion.

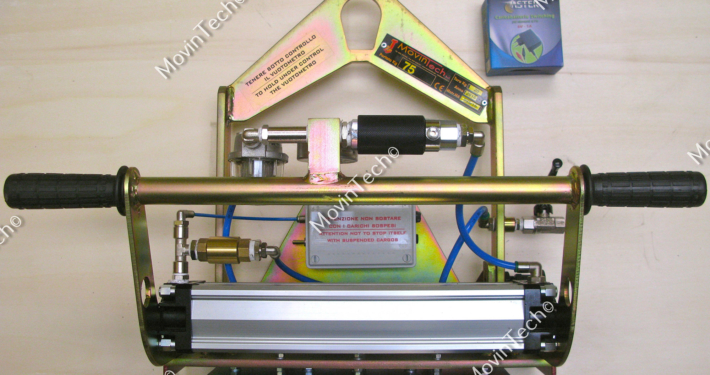

Suction cups – In case of compressed air operation, the vacuum generator (venturi meter) is mounted directly on the suction cup.

The system normally consists of a suction cup with venturi meter + connection pipe.

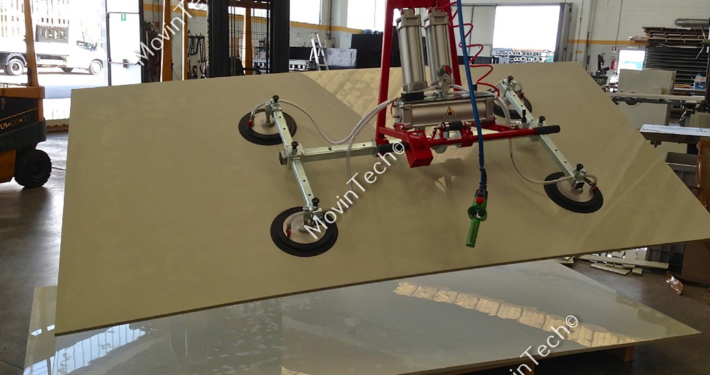

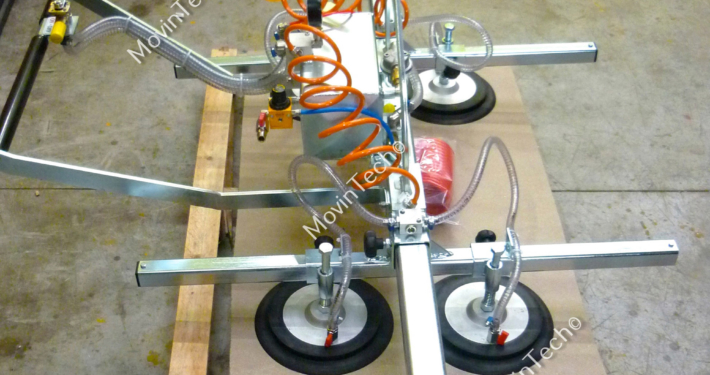

One of the necessary and indispensable conditions to obtain the functional compliance of the suction cup for the service for which it is intended, consists in the correct choice of the model (single plate, two plate, multi plate, flexible – with manual or pneumatic tipping).

The parameters that must be carefully considered when making the choice are:

Capacity: one must take into account the maximum weight to be lifted and increased in case of flexible materials, inclination of the load with respect to the horizontal, dynamic inertia, etc.

Load capacity from 50 to 3000 kg

For several years now, even in the handling of non-magnetic materials, the use of suction cups has been widespread. Combined with lifting equipment, these allow the handling of non-porous materials by exploiting the depression created by a vacuum generator and limited by the surface of the suction cup or suction cups that grip the material to be lifted.

Our suction cups are

– built with a broad use of special materials.

– tiltable 90°, with manual or pneumatic tilting, for gripping and laying of materials, both vertically and horizontally.

– equipped with special shape and material gasket to allow the grip on all materials, polished, raw, flamed, bush-hammered, etc.

– in compliance with the Machinery Directive.

– equipped with safety devices: pre-empty tank, vacuum gauge, vacuum switch, luminous acoustic alarm system.

Customized solutions are studied and adapted to the different handling requirements.

The vacuum is obtained by means of an electric pump or a vacuum generator running on compressed air (venturi meter).

The system normally consists of the vacuum pump + connection pipe + suction cup. The vacuum pump must be positioned close to the place of use.

For special applications we supply pumps with single-phase electric motors, direct current (for installation on self-propelled vehicles powered by the batteries of the vehicle itself), with internal combustion.

Suction cups – In case of compressed air operation, the vacuum generator (venturi meter) is mounted directly on the suction cup.

The system normally consists of a suction cup with venturi meter + connection pipe.

One of the necessary and indispensable conditions to obtain the functional compliance of the suction cup for the service for which it is intended, consists in the correct choice of the model (single plate, two plate, multi plate, flexible – with manual or pneumatic tipping).

The parameters that must be carefully considered when making the choice are:

Capacity: one must take into account the maximum weight to be lifted and increased in case of flexible materials, inclination of the load with respect to the horizontal, dynamic inertia, etc.

Dimensions and shape: flat, concave or convex, regular or irregular element.

Nature of the load: compact, rigid or flexible material, polished or rough surface, etc.

Type of lifting equipment used: jib crane, overhead crane, self-propelled vehicle, etc.

Type of suction cups:

With 1 or more plates

With venturi pump

With Electric pump

Suction cup for use with sheet metal

Suction cup for use with aluminium

Suction cup for use with marble

Suction cup for use with wood

Suction cup for use with glass

Autonomous suction cup with batteries