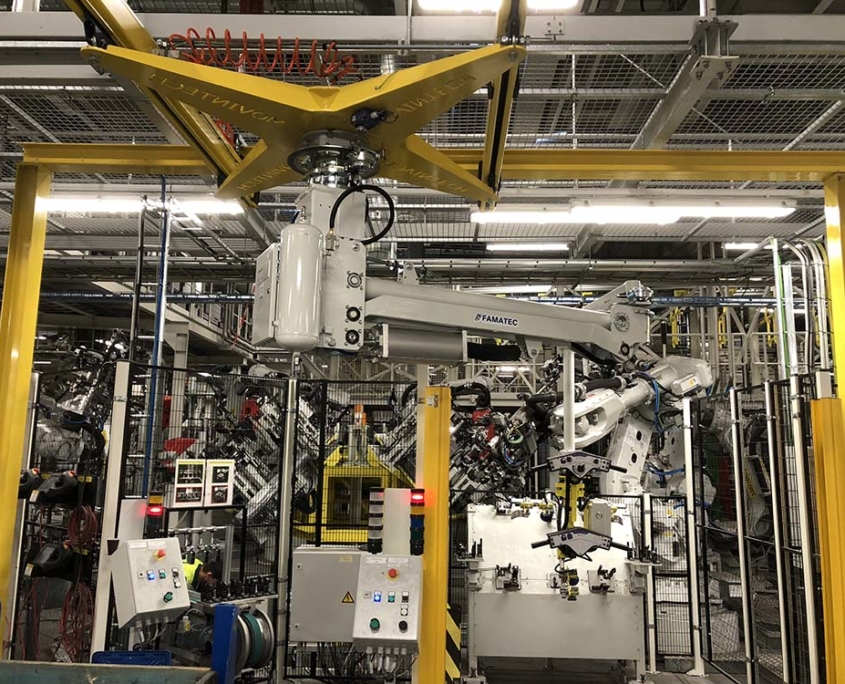

Pneumatic manipulators

Manipulators for manual handling of loads (MMC) and reduction of the risk of musculoskeletal disorders (MSDs).

Manipulators, by simulating human handling, drastically reduce the risk of injuries due to product handling during processing.

The operator can manually handle heavy, bulky, dangerous products with minimum effort and sensitive and precise control.

It reduces the risk of occupational diseases due to physical effort and the risk of exposure to accidents.

There are many systems that guarantee safety in different possible critical situations:

- Product gripping not performed effectively; the manipulator remains inactive.

- This occurs when the safety conditions of the gripping system do not reach the minimum set values and/or the gripping sensors are not correctly activated.

- Risk of crushing fingers while gripping or releasing the product; both hands are needed to perform the commands.

- The control console is equipped with two spaced control buttons that the operator must press simultaneously.

- Drift movements of the boom in rest position; the manipulator is equipped with parking brakes.

- The parking brakes are disc type and self-centring calliper brakes, they are present on the rotation axis of the column, intermediate and rotation axis of the gripping system, they are active even in case of lack of air supply and they are can be activated directly from the console.

- Sudden lack of compressed air supply or insufficient pressure; the product is automatically and slowly lowered to the lowest point before being released.

- To contain the effects of this event, the system is equipped with:

- Certified tank that guarantees a regular air flow in case of discontinuous supply and, in case of a sudden power failure, allows the completion of the work cycle.

- Non-return valve located upstream of the tank.

- Special safety valve that prevents violent downward and upward movements of the boom.

- Pneumatic system designed to sequence the effects of pressure drop, the last step is the release of the product.

- Erroneous release command during handling; the product is automatically and slowly lowered to the lowest point.

- The pneumatic logic intercepts the erroneous intention of the operator and, before releasing the product, commands the lowering at controlled speed. The console is equipped with a double release button to avoid unintentional operator commands.

Movintech solutions improve the well-being of the workstation, making it suitable for all staff members, regardless of their physical potential, gender and seniority. They improve productivity, which becomes constant throughout the entire working day. They improve production quality, with virtually no risk of damage to products during handling or damage to production equipment.

Pneumatic manipulators are of different types

With rigid or flush booms

Suspended or with column

With self-stabilized column

The manipulators are to be used to move sheet metal, glass, wood, cement, chemical and food industry material, difficult to grip items.